Pallet Racking Systems Trends to rack your inventories in Warehouse

Pallet racking is the most common form of warehouse racking systems, that is designed to store materials in horizontal rows with multiple levels. But the key is that why do you spend more money to add square feet when you have an option to utilize your vertical space.

The Pallet Racking system can be classified mainly into 6 types:

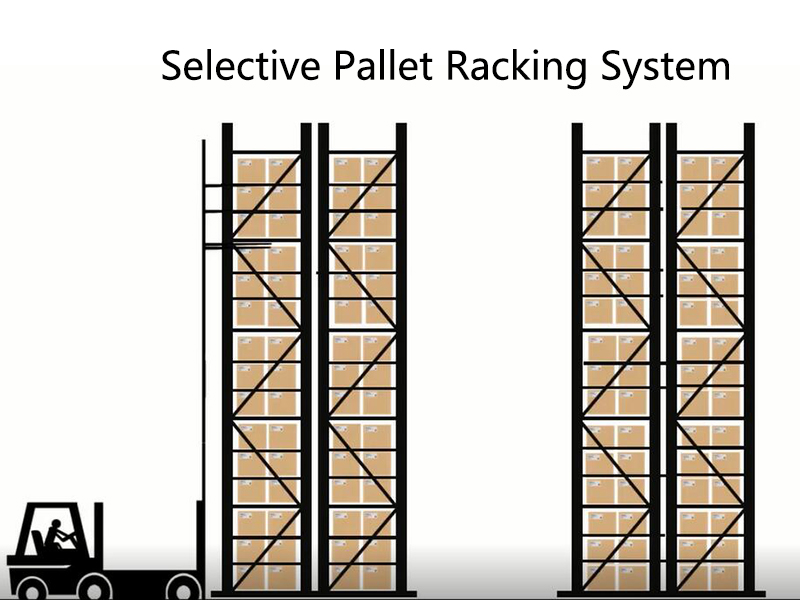

1.Selective Pallet Racking System

2.Double Deep Pallet Racking System

3. Drive in and Drive thru Pallet Racking System

4.Very Narrow Aisle (VNA) Pallet Racking System

5. Gravity Flow Pallet Racking System

6.Push back Pallet Racking System

1.Selective Pallet Racking System

Advantages:

- Structure Costs is less

- Easy installation and configuration

- Better stock rotation

- Easy order picking and 100% selectivity

- Direct access to inventories

- High density storage

- This can be used in conjunction with all types of trucks

Suitable for Customers:

- FMCGs

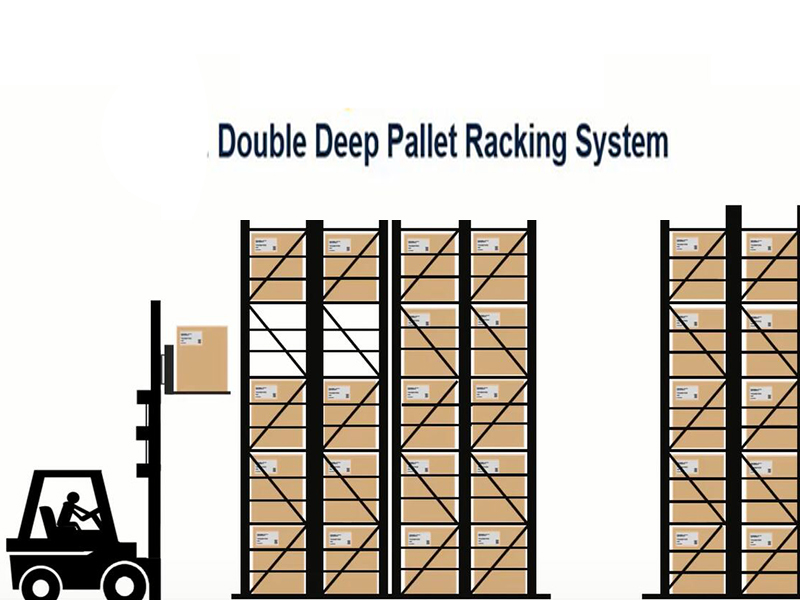

2.Double Deep Pallet Racking System

Advantages:

- Around 30% more capacity than Selective Pallet Racking System

- Less expensive comparing with Drive In Racking, but increases capacity by up to 30%

- This might not require high number of homogeneous pallet types

Suitable for Customers:

- Place where Drive In Racking are not possible

- Better Density and Better Storage – maximum cubic space

- Reduces aisles space increases cubed space utilization

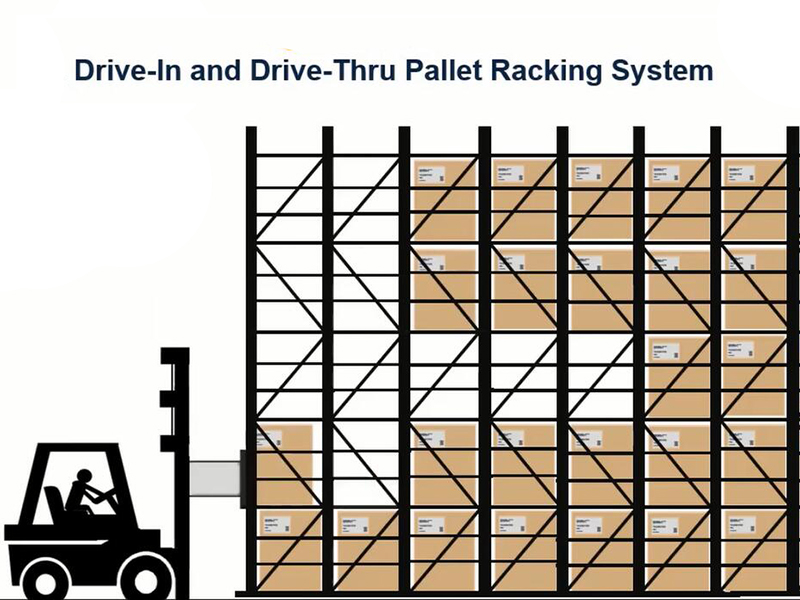

3.Drive in and Drive thru Pallet Racking System

1.Drive-In Pallet Racking System

This loads and retrieves from the same side, creating First-In-Last-Out (FILO) inventory retrieval.

2.Drive-Thru Pallet Rack Systems

This loads from one side and unload from the other to create First-In-First-Out (FIFO) inventory retrieval. Advantages:

- Density Storage is much more maximizing cubic space

- Reduces aisles space further increases cubed space utilization

- Maximum pallets stored per cubic meters than any other storage systems

Suitable for Customers:

- Bulk goods of the same type

- Best for cold and chill storage applications

- Perfectly suitable for seasonal goods

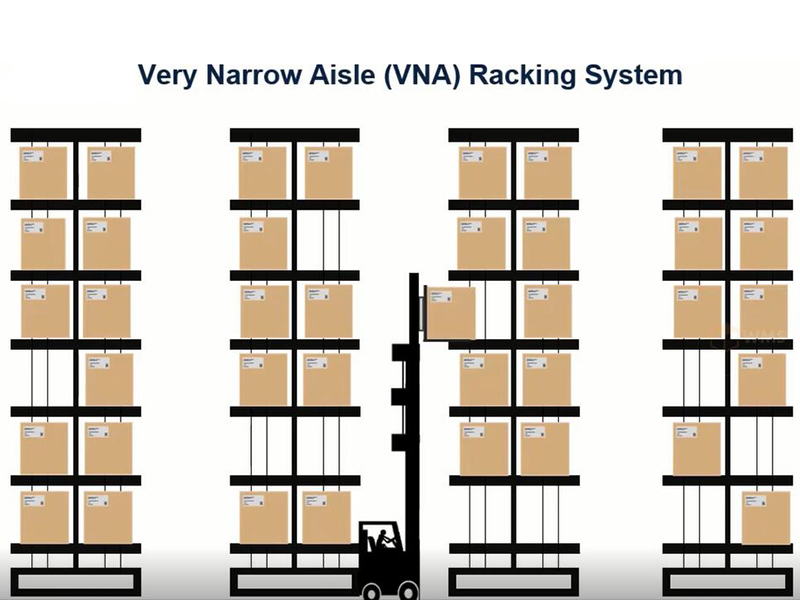

4.Very Narrow Aisle (VNA) Pallet Racking System

Advantages:

- Better stock rotation

- Perfect order picking and 100% selectivity

- Rapid handling

- Increased space by an additional 40-50% over Selective pallet Racking system

- Uses guide rails or wire guidance for fast movement in aisle

- Maintain FIFO

Suitable for Customers:

Need a super flat floor

FMCG

Different categories of Goods

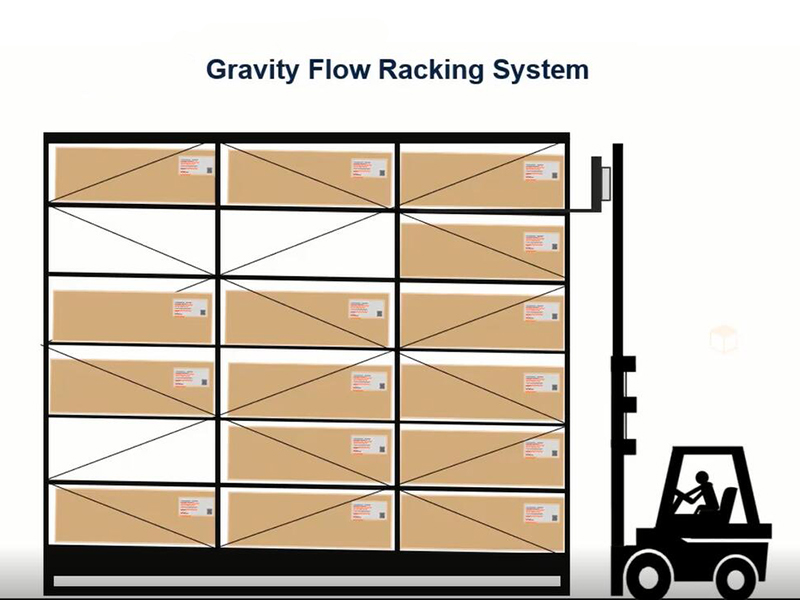

5.Gravity Flow Pallet Racking System

Advantages:

- Up to 50-60% less floor space than conventional pallet racking

- FIFO provides automatic stock rotation.

- Dedicated load and retrieval faces mean only two fork truck aisles are required

- Better speed of operation within the warehouse

Suitable for Customers:

Need first-in first-out principle

Drinks industry

Only two fork truck aisles are required, one for loading and one for retrieval

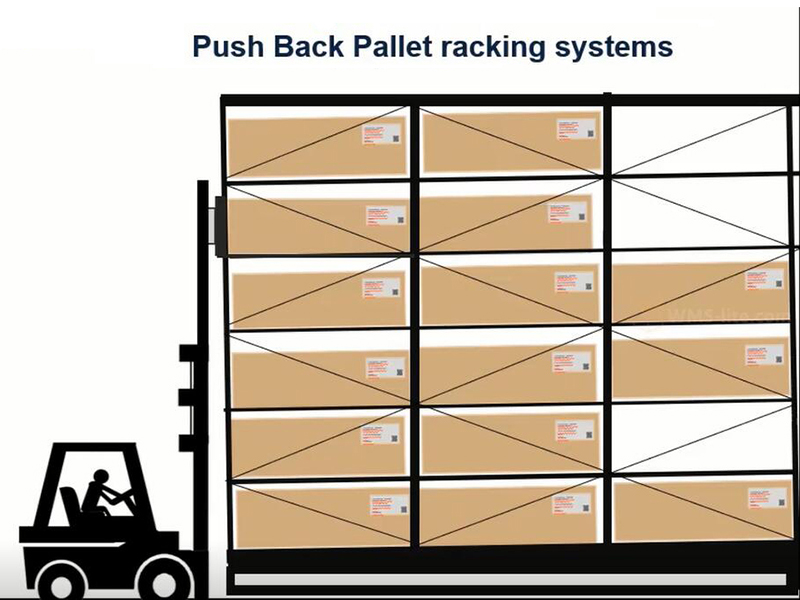

6.Push Back Pallet racking system

Advantages:

- High Density Storage- maximizing cubic space

- Not Aisles

- Quick easy access to different size of pallet types

- Pallet automatically presented at the rack pick face

- Reduces truck travel distances, and cuts cycle times

Suitable for customers:

Food Distribution

Manufacturing

Third Party Logistics Facilities

Automotive

Pharmaceuticals

Overall performance rating of Pallet Racking System