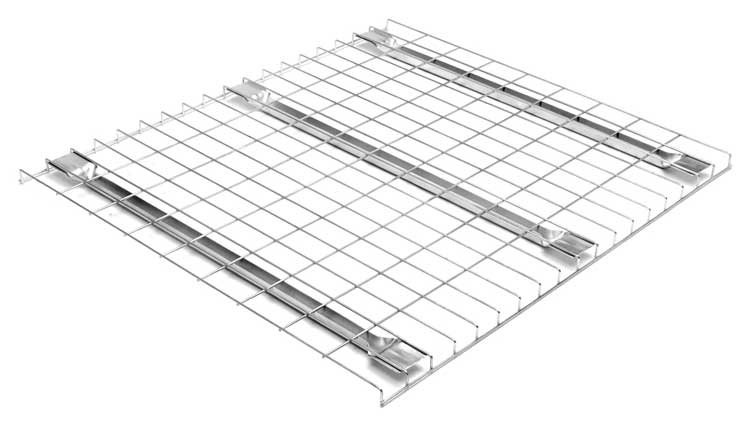

Wire mesh decking for pallet rack

The raw materials of steel wire mesh decking are generally made of the best cold drawing and spray welding, and the standard mesh size of the wire mesh decking is 50*50. The bottom is reinforced with ribs, and both sides are bent and placed on the shelf beams to ensure the safety of the goods. The general load capacity can reach 3T, and the surface treatment is galvanized and spray-coated.

Generally, wire mesh decks are usually welded by cold-drawn wire and U-shaped profiles. It has excellent fire resistance and is both waterproof, moisture-proof and rust-proof. It can be designed according to user needs with shelf specifications and meets environmental protection standards.

Generally, the wire mesh decking is made according to the size of the heavy-duty warehosue racks. According to the different load-bearing requirements, the production styles of the shelf wire mesh decking are also different. The general ones can be summarized as follows:

Wire diameter: 5.0, 6.0, 6.4 and 8.0;

Mesh: 50*50, 50*100, 25*25, 50*25;

Reinforcing ribs: Generally U-shaped steel with an open length of 110mm, with both ends flattened.

Support slot: 2.0mm board. It is more cost-effective than wooden pallets, has better sturdiness, and is durable and profitable for recycling.

Wire mesh decks are also often used in warehouse pallet rack projects and occupy a very important part. They also have unique advantages in logistics storage. The main conveniences are as follows:

1. On the premise that the original floor area remains unchanged, the load-carrying space ratio is increased and the warehouse volume ratio is improved. Compared with the construction of steel structure warehouses, investing in the construction of pallet racks has the characteristics of low investment, short construction period, quick results, adjustable and movable.

2. The use of wire mesh decks can improve warehouse utilization, asset utilization, and yield, which is generally equivalent to 1.5-2.5 times the storage capacity of flat warehouses, and warehousing income increases in the same proportion.

3. Improve the efficiency of goods entering and exiting the warehouse, which is beneficial to shelf rack storage, reduces damage to goods, and improves the quality of logistics services.