How Gravity Roller Racking Works?

We all know that each warehouse storage racking has its own unique functional characteristics, which will be divided into simpler storage racking and more complex racking. Gravity roller racking are more complicated in structure and need more parts during theinstallation.

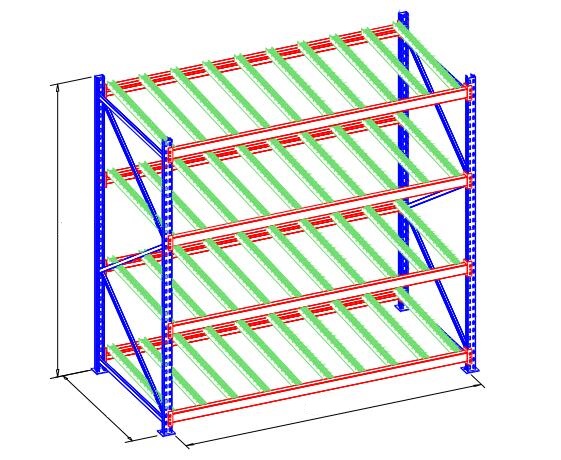

In fact, gravity roller racking have evolved from pallet racks, except that pallet racks use pallets to store goods, while gravity roller racking use roller tracks. The working mode of gravity roller racking is special. The characteristic of gravity roller racking is to use gravity to transport goods, so it is not difficult to find by observation. In fact, the structure of gravity roller racking is different from pallet racks. The Beams are horizontal, but gravity racks are different.

The biggest feature of gravity roller racking is to use gravity to transport goods, install special roller tracks, and design a certain slope, so that when the goods are placed on the pallet racks, they will automatically move to the inside of the racking. The entire transportation process is automated. However, the angle of the gravity rack is not suitable, and the angle will cause the goods to fall too fast. This will cause collisions and damage to the goods or the racking, which will cause unnecessary losses to the company.

There are a lot of precautions during the use of gravity roller racking. For example, if the ramp is long, some damping devices can be properly installed. This device can serve as a buffer to ensure that the goods cannot slide down too quickly.